Manufacturing processes continually evolve, presenting many challenges to ensure consistent product quality. Maintaining high standards, from complex supply chains to intricate production workflows, is paramount. In this context, defect detection emerges as a critical aspect of the manufacturing process, holding the key to enhancing overall product quality and customer satisfaction.

Manufacturing Quality Challenges

The landscape of modern manufacturing is fraught with challenges, ranging from stringent quality standards to the intricacies of managing diverse raw materials. Production lines must contend with variations in materials, equipment, and environmental factors, making it increasingly difficult to achieve uniform excellence across the board. As a result, the need for effective quality control mechanisms has become more pronounced than ever.

Importance of Defect Detection in the Manufacturing Process

Defects in manufactured products lead to customer dissatisfaction and incur significant costs for manufacturers. Identifying and rectifying defects early in the production cycle is essential to prevent defective items from reaching consumers and to minimise waste. Beyond economic considerations, maintaining a reputation for high-quality products is vital for sustaining customer trust and loyalty in a competitive market.

Introduction to Smart Assistants for Process Monitoring

Enter the era of smart manufacturing, where technological advancements are revolutionising traditional production methods. Smart assistants, equipped with artificial intelligence and IoT capabilities, have emerged as powerful tools for real-time process monitoring. These intelligent systems can analyse vast amounts of data, quickly identifying anomalies and defects during manufacturing. In this blog post, we delve into the role of smart assistants in defect detection and how they contribute to elevating manufacturing quality to new heights.

The Need for Advanced Process Monitoring

In the dynamic manufacturing landscape, traditional quality control methods often fail to address the complexities of modern challenges. While conventional approaches have served their purpose in the past, the advent of sophisticated production techniques, global supply chains, and increased product intricacies have exposed their limitations. It is imperative to assess how traditional methods compare to the demands of contemporary manufacturing environments.

Key Shortcomings in Conventional Defect Detection

Conventional defect detection methods, relying heavily on manual inspection and periodic sampling, face limitations in detecting subtle defects or anomalies in real-time. Human error, subjectivity, and the inability to process large volumes of data swiftly contribute to the inadequacy of these approaches. As manufacturing processes become more intricate, the need for precision and efficiency in defect identification has become more pressing, necessitating a shift towards more advanced and automated monitoring solutions.

Importance of Real-time Monitoring in Improving Efficiency

The pace of modern manufacturing demands real-time insights into production processes. Delayed defect detection not only leads to increased costs associated with rework and waste but can also impact the overall efficiency of the production line. Real-time monitoring allows instantaneous identification of deviations from quality standards, enabling proactive interventions to rectify issues promptly. Integrating advanced technologies like smart assistants facilitates a seamless transition to a more responsive and efficient manufacturing ecosystem. In the subsequent sections, we explore how these innovations in process monitoring can address the shortcomings of traditional methods and contribute to a more robust quality control framework.

The Role of Smart Assistants in Manufacturing

Smart assistants in manufacturing are intelligent systems designed to revolutionise the monitoring and control of production processes. Leveraging cutting-edge technologies such as artificial intelligence (AI) and the Internet of Things (IoT), these assistants exhibit a range of capabilities beyond the scope of traditional methods. With the ability to collect, analyse, and interpret data in real-time, smart assistants are pivotal in reshaping how manufacturers approach quality control.

How Smart Assistants Enhance Process Monitoring

The enhancement of process monitoring through smart assistants is multifaceted. These intelligent systems excel at continuous data collection from various points in the manufacturing pipeline, offering a comprehensive view of the entire production cycle. By harnessing machine learning algorithms, smart assistants can quickly identify patterns, anomalies, and potential defects, even in highly intricate processes. Their adaptive nature allows them to learn and evolve, continuously refining their defect detection capabilities. This dynamic approach to process monitoring enables manufacturers to proactively address issues, reduce downtime, and optimise overall production efficiency.

Overview of Technologies Involved (e.g., AI, IoT)

At the heart of smart assistants lies a synergy of advanced technologies. Artificial intelligence empowers these systems to analyse vast datasets, recognise patterns, and make informed decisions without human intervention. Integrating the Internet of Things facilitates real-time connectivity between devices and machines, enabling seamless communication and data exchange within the manufacturing environment. Through a combination of AI and IoT, smart assistants create a networked ecosystem that promotes efficient, automated, and intelligent monitoring, ultimately contributing to the early detection and prevention of defects in the production process. In the subsequent sections, we will explore the benefits of amalgamating these technologies to pursue superior manufacturing quality.

Benefits of Utilizing Smart Assistants

One of the paramount advantages of incorporating smart assistants into manufacturing is the substantial improvement in defect detection accuracy. Unlike traditional methods that may rely on manual inspection or periodic sampling, smart assistants equipped with advanced algorithms and machine learning capabilities can meticulously analyse vast datasets in real-time. This heightened precision enables the early identification of even the most subtle anomalies, significantly reducing false negatives and positives. By enhancing defect detection accuracy, manufacturers can ensure higher product quality, reducing the likelihood of faulty items reaching the end consumer.

Increased Operational Efficiency

Smart assistants bring a transformative impact on operational efficiency within manufacturing facilities. By continuously monitoring processes in real time, these intelligent systems enable proactive responses to deviations from established standards. Swift identification of issues allows for immediate corrective actions, minimising downtime and optimising the overall efficiency of production lines. The seamless integration of smart assistants into existing workflows ensures a streamlined and adaptive approach to manufacturing, fostering a more agile and responsive environment that aligns with the dynamic demands of modern production.

Cost Savings and Waste Reduction

Implementing smart assistants in defect detection contributes significantly to cost savings and waste reduction throughout the manufacturing cycle. Through early identification of defects, manufacturers can minimise the need for extensive rework, preventing the production of defective items that would otherwise lead to increased costs. Moreover, by addressing issues in real-time, smart assistants help reduce overall waste, enhance resource utilisation and promote sustainability. The efficiency gains and waste reduction achieved by smart assistants translate into a more cost-effective and environmentally conscious manufacturing process. In the subsequent sections, we will explore real-world case studies and delve deeper into the practical applications of smart assistant solutions in diverse manufacturing scenarios.

Implementing Smart Assistant Solutions

The successful incorporation of smart assistant solutions into manufacturing operations requires a strategic approach to integration. Seamless assimilation into existing processes is crucial to ensure minimal disruption and maximum efficiency gains. Manufacturers must carefully evaluate their current workflows, identifying key touchpoints where smart assistants can add value.

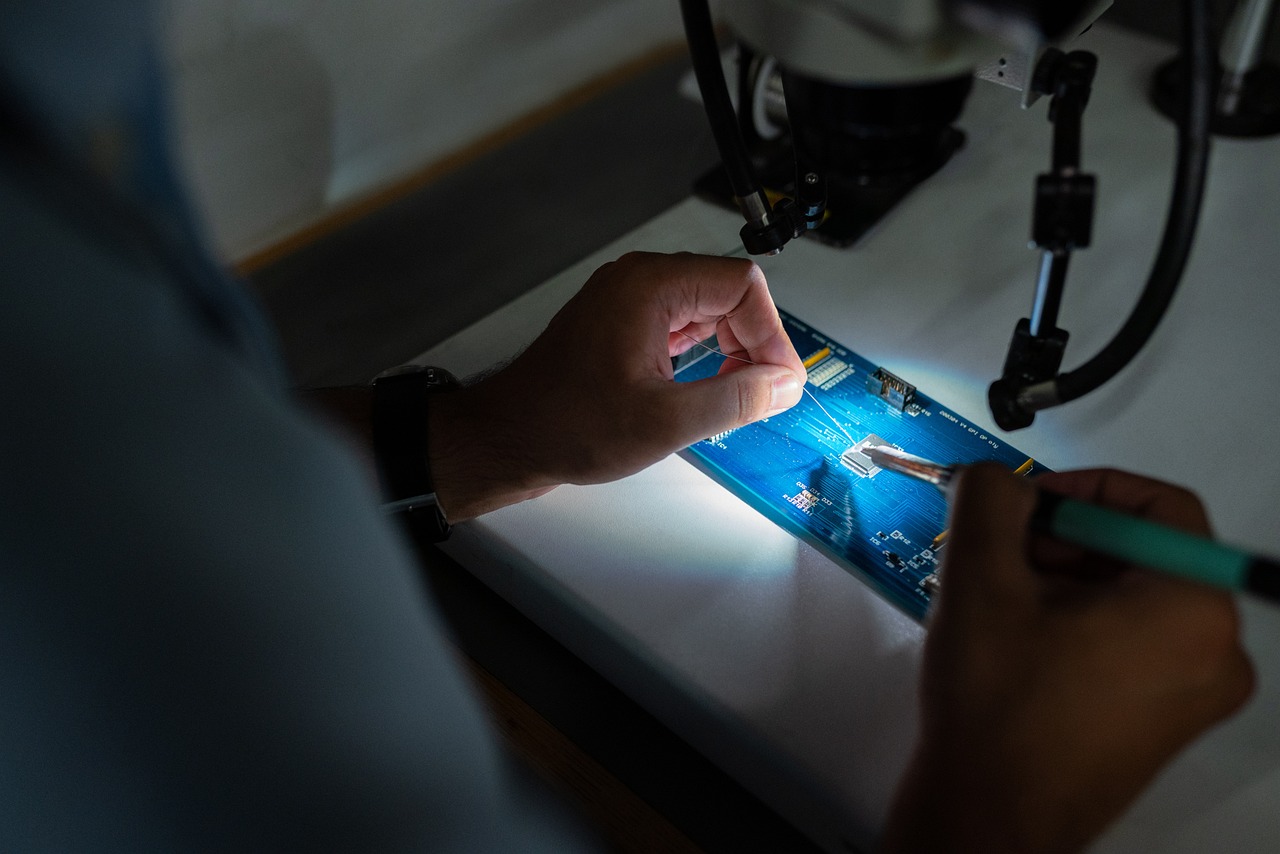

Training and Adapting Smart Assistants to Specific Needs

Training smart assistants to meet the specific needs of a manufacturing environment is a pivotal step in maximising their effectiveness. This involves customising algorithms and machine learning models to align with the intricacies of the production process. Effective training ensures that smart assistants can accurately recognise and categorise defects unique to a particular industry or product. Additionally, ongoing adaptation is essential to accommodate changes in production parameters and evolving quality standards.

Addressing Potential Challenges and Concerns

Despite the numerous benefits, implementing smart assistants in manufacturing may encounter challenges and evoke concerns. This section critically examines potential hurdles, such as data security and privacy issues, integration complexities, and workforce adjustments. By proactively addressing these challenges, manufacturers can navigate the transition smoothly and capitalise on the full potential of smart assistant solutions. Strategies for mitigating concerns, fostering employee acceptance, and ensuring compliance with industry regulations will be explored to provide a comprehensive understanding of the considerations involved in successfully implementing smart assistants in manufacturing processes.

Future Trends and Innovations

The evolution of smart assistant-driven manufacturing continues to be shaped by a wave of emerging technologies that promise to revolutionise the industry further. This section explores the cutting-edge technologies that are gaining traction in smart manufacturing. The landscape is dynamic and evolving, from advancements in artificial intelligence and machine learning algorithms to the integration of augmented reality and advanced sensor technologies. Understanding these emerging technologies is essential for manufacturers seeking to stay at the forefront of innovation and harness the full potential of smart assistants.

Anticipated Developments and Their Potential Impact

Several anticipated developments are poised to impact smart assistant-driven manufacturing profoundly. This section delves into the potential trajectory of these innovations and their implications for the industry. The future holds exciting possibilities, from enhanced predictive analytics capabilities to blockchain integration for secure data sharing. Additionally, the convergence of smart assistants with 5G technology is expected to facilitate faster and more reliable communication between devices, opening up new avenues for real-time monitoring and control. By anticipating these developments, manufacturers can strategically position themselves to adopt and leverage upcoming technologies, ensuring sustained competitiveness in an ever-evolving landscape.

As we peer into the future of manufacturing, it becomes clear that the role of smart assistants will continue to expand, driven by the relentless pace of technological advancement. The subsequent sections of this blog will explore real-world case studies, providing insights into successful implementations of smart assistant solutions and highlighting the tangible benefits experienced by manufacturers across various industries.

Considerations for Implementation

Adopting smart assistants in manufacturing is a strategic choice that warrants careful consideration of various factors. This section examines key concerns such as the complexity of manufacturing processes, the existing technological infrastructure, and the organisational readiness for technical integration. Assessing the compatibility of smart assistants with specific industry requirements and the potential impact on workforce dynamics is crucial in making an informed decision. By thoroughly weighing these factors, manufacturers can determine the viability and appropriateness of integrating smart assistants into their operations.

Customisation for Different Manufacturing Environments

Manufacturing environments are diverse, with each industry having unique challenges, processes, and quality standards. Smart assistants must be customised to align seamlessly with these specific manufacturing environments to maximise their effectiveness. This involves tailoring algorithms, machine learning models, and sensor configurations to suit the intricacies of different production lines. This section explores the importance of customisation in ensuring that smart assistants become valuable assets that enhance, rather than disrupt, the existing manufacturing ecosystem. Strategies for adapting these intelligent systems to diverse settings will be discussed to guide manufacturers through the customisation process.

Cost-Benefit Analysis and Return on Investment Considerations

While the potential benefits of smart assistants in manufacturing are substantial, it is imperative to conduct a comprehensive cost-benefit analysis before implementation. This involves evaluating the initial investment required for technology adoption, ongoing maintenance costs, and potential savings achieved through improved defect detection and operational efficiency. Return on investment considerations encompass monetary gains and factors such as enhanced product quality, reduced waste, and increased customer satisfaction.

Challenges and Solutions

Implementing smart assistants in manufacturing, while promising, is challenging. This section identifies and addresses common hurdles encountered when integrating these intelligent systems. Challenges may include resistance to change from the workforce, data security concerns, and the need for comprehensive training programs. By acknowledging and understanding these challenges, manufacturers can proactively develop strategies to mitigate potential roadblocks and ensure a smoother transition to a smart assistant-driven manufacturing environment.

Strategies to Overcome Potential Obstacles

Effective strategies are essential for overcoming obstacles while implementing smart assistants. This section explores proactive measures to address challenges, such as fostering a culture of innovation and collaboration within the organisation, providing comprehensive training for employees to adapt to new technologies, and implementing robust cybersecurity measures to safeguard sensitive data. Effective communication and change management strategies will also be discussed to ensure a cohesive and well-managed implementation process. By employing these strategies, manufacturers can navigate challenges more effectively and maximise the benefits of smart assistant solutions.

Continuous Improvement and Updates

The manufacturing landscape is dynamic, with technology and industry standards evolving. Continuous improvement and regular updates are imperative to ensure the sustained effectiveness of smart assistant solutions. This section emphasises the importance of monitoring system performance, gathering feedback from users, and incorporating advancements in technology to enhance the capabilities of smart assistants. Manufacturers must adopt a mindset of continuous improvement, treating the implementation of smart assistants as an ongoing process rather than a one-time event. By staying agile and responsive to changes, businesses can future-proof their manufacturing processes and remain at the forefront of innovation.

Benefits of Using Smart Assistants in Manufacturing

In conclusion, integrating smart assistants into manufacturing processes offers myriad benefits that significantly impact the quality and efficiency of production. From improved defect detection accuracy to increased operational efficiency and substantial cost savings, smart assistants play a transformative role in elevating manufacturing standards. This section recaps the key advantages, emphasising how these intelligent systems contribute to enhanced product quality, streamlined operations, and a more sustainable and competitive manufacturing landscape.

Encouragement for Businesses to Embrace Advanced Process Monitoring

The future of manufacturing lies in embracing advanced process monitoring through technologies like smart assistants. This section encourages businesses to recognise the value and potential of these intelligent systems in staying ahead of industry demands. Embracing advanced process monitoring is not merely an option but a strategic imperative for organisations aspiring to achieve and maintain excellence in product quality. The proactive adoption of smart assistants positions businesses to navigate the evolving manufacturing landscape, providing a competitive edge in an increasingly dynamic and technology-driven marketplace.

Future of Defect Detection in Manufacturing

As we look to the future, the role of defect detection in manufacturing will continue to evolve, driven by technological advancements. Smart assistants represent a pivotal step towards a future where defects are identified and addressed in real time, ensuring the delivery of high-quality products to consumers. This section offers final thoughts on the ongoing evolution of defect detection, highlighting the potential for continuous improvement and innovation. By staying abreast of emerging technologies and industry trends, manufacturers can pave the way for a future where defect detection becomes not only a reactive process but a proactive and integral part of the manufacturing journey.

In concluding this exploration of smart assistant-driven manufacturing and its impact on defect detection, we aim to inspire businesses to embrace the transformative potential of these technologies. The path to manufacturing excellence is illuminated by the capabilities of smart assistants, setting the stage for a future where precision, efficiency, and quality converge seamlessly in the production process.

Let's dive right into how Iwoscan can reshape your manufacturing pipeline

Let's dive right into how Iwoscan can reshape your manufacturing pipeline

Comments

No comments yet!Add a Comment

You must be logged in to post a comment.