Inconsistent Takt Time

Takt time inconsistencies lead to production delays and customer dissatisfaction, impacting operational efficiency and profitability.

Takt time, the heartbeat of your production line, is crucial for maintaining efficiency and meeting customer demands. Discover how Iwoscan revolutionises your Takt time management, ensuring every second counts.

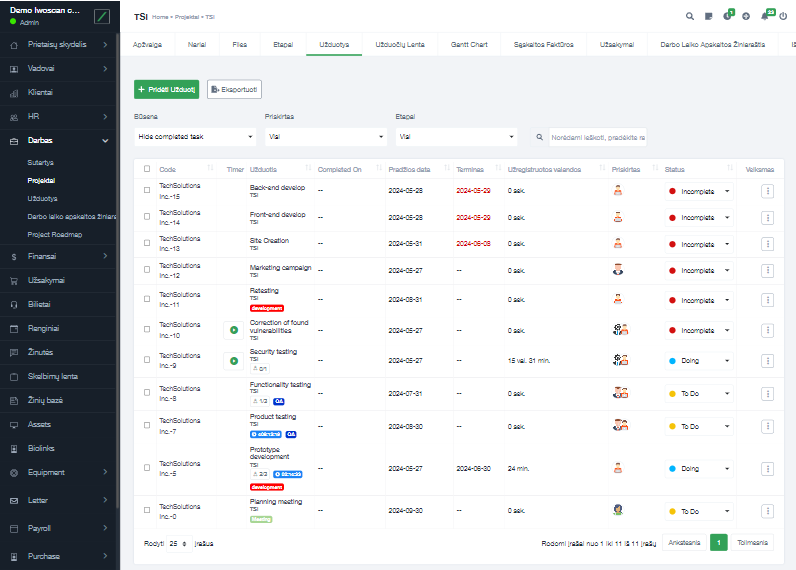

Odoo ERP friendly

Odoo ERP friendly Built-in task splitting and merging

Built-in task splitting and merging Raw data without distortion

Raw data without distortion

Explore how Iwoscan's innovative features and benefits empower you to optimise production pace, streamline processes, and achieve manufacturing excellence.

Our feature set is engineered to empower your business with precision, security, and comprehensive insights, ensuring you stay at the forefront of innovation in your industry.

Enhance your operations through real-time process monitoring, effective anomaly tracking, and instant insights within a user-friendly interface to optimise processes.

Optimise your operations by implementing employee productivity monitoring, production anomalies tracking, and enhancing quality control efficiency.

Get instant access to critical data and analytics, enabling swift decision-making and precise performance evaluation, all within the Iwoscan platform.

Iwoscan provides robust data security, ensuring your information remains safe and accessible on the device for up to two years, giving you peace of mind and long-term data retention capabilities.

Facilitate effortless communication with your workforce, harness performance recognition and reward functionalities, and establish ongoing feedback loops for continuous improvement.

An intuitive interface ensures effortless process optimisation, complemented by a crystal-clear LED display for enhanced visibility.

Choose from various flexible data export formats, including CSV, JSON, HTML table, and binary. Additionally, you can generate reports directly in your web browser or download raw data in .csv format.

Maximise your efficiency with the integrated text input for event logging, precise timing using clock functionality, and versatile data capture with built-in barcode reading and RFID capabilities, ensuring seamless operations and comprehensive tracking of events.

Achieve smooth Wi-Fi communication, simplified device setup, and operation, while interactive dashboards provide precise insights for enhancing operational efficiency, making the most of your connected experience.

Our system operates independently, ensuring no reliance on external servers for basic data processing, guaranteeing your data's security and availability.

In manufacturing efficiency, Takt time discrepancies pose significant hurdles, impacting productivity and customer satisfaction. Explore how Iwoscan, your dedicated Takt Time Enhancement Partner, tackles key issues, optimises production pace, and nurtures operational excellence.

Takt time inconsistencies lead to production delays and customer dissatisfaction, impacting operational efficiency and profitability.

Manual Takt time monitoring is error-prone, increasing the risk of production pace variations and disrupting workflow synchronization.

Inefficient processes hinder adherence to Takt time requirements, resulting in increased production costs and reduced competitiveness.

Handling vast Takt time data can overwhelm teams, making it challenging to identify deviations and make timely adjustments.

Navigating complex production standards and meeting Takt time targets poses risks of non-compliance, which can lead to operational disruptions.

Imagine a reality where efficiency is second nature, productivity soars, and bottlenecks vanish. We're about to unveil solutions that will make your workplace a hub of unparalleled excellence.

Let's make your vision a reality!

Iwoscan is a comprehensive solution designed to enhance Takt's time management. It offers real-time monitoring, data analysis, and insights to help organisations optimise production pace and streamline processes.

Iwoscan is versatile and adaptable to various industries, including manufacturing, automotive, electronics, and more. Its flexibility makes it suitable for any sector that requires precise Takt time management.

Iwoscan's real-time monitoring feature detects Takt time deviations as they occur, enabling organisations to maintain a consistent production pace and minimise delays, ensuring efficiency.

Yes, Iwoscan minimises manual monitoring errors by automating Takt time tracking. It reduces the likelihood of human errors, resulting in more precise Takt time management.

Iwoscan identifies process inefficiencies that may hinder adherence to Takt time. It provides insights to help organisations make necessary adjustments, ensuring that production meets Takt time targets consistently.

Iwoscan simplifies data management by offering data analysis tools and secure storage options. It helps teams handle and interpret Takt time data effectively, ensuring that actionable insights can be extracted.

Iwoscan helps organisations adhere to Takt time requirements while navigating complex production standards and regulations. It offers real-time monitoring and reporting to ensure compliance.

Yes, Iwoscan provides customisation options to tailor its features to an organisation's specific Takt time management requirements. This enables businesses to focus on areas that matter most and optimise resources effectively.

Iwoscan facilitates continuous Takt time improvement by providing ongoing insights into production pace performance. By analysing real-time data, organisations can identify areas for enhancement and implement corrective actions for sustained efficiency.

Certainly, Iwoscan enhances Takt's time management, streamlines processes, and ensures consistency, ultimately bolstering an organisation's reputation for delivering on time and efficiently. It helps build trust with customers and stakeholders alike.