Adaptability to Unforeseen Events

Manufacturing downtime leads to substantial financial losses, averaging $260,000 per hour, necessitating real-time monitoring and early intervention provided by Iwoscan to prevent costly disruptions.

Understand the pivotal role of Iwoscan in achieving task-splitting success, particularly in the seamless consolidation of subtasks, contributing to enhanced efficiency in manufacturing processes.

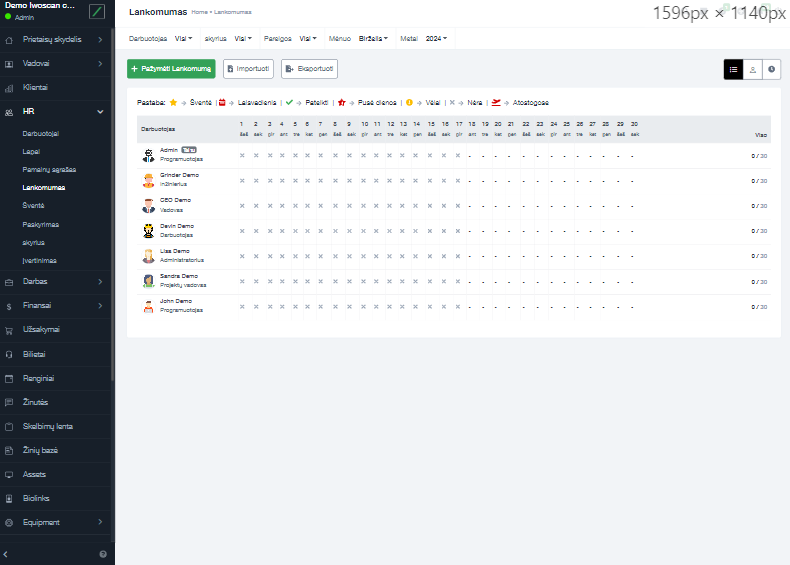

Odoo ERP friendly

Odoo ERP friendly Built-in task splitting and merging

Built-in task splitting and merging Raw data without distortion

Raw data without distortion

Iwoscan is the future of manufacturing defect detection, tracking, and analysis ally. We're not just a solution; we're your path to manufacturing excellence.

Our feature set is engineered to empower your business with precision, security, and comprehensive insights, ensuring you stay at the forefront of innovation in your industry.

Enhance your operations through real-time process monitoring, effective anomaly tracking, and instant insights within a user-friendly interface to optimise processes.

Optimise your operations by implementing employee productivity monitoring, production anomalies tracking, and enhancing quality control efficiency.

Get instant access to critical data and analytics, enabling swift decision-making and precise performance evaluation, all within the Iwoscan platform.

Iwoscan provides robust data security, ensuring your information remains safe and accessible on the device for up to two years, giving you peace of mind and long-term data retention capabilities.

Facilitate effortless communication with your workforce, harness performance recognition and reward functionalities, and establish ongoing feedback loops for continuous improvement.

An intuitive interface ensures effortless process optimisation, complemented by a crystal-clear LED display for enhanced visibility.

Choose from various flexible data export formats, including CSV, JSON, HTML table, and binary. Additionally, you can generate reports directly in your web browser or download raw data in .csv format.

Maximise your efficiency with the integrated text input for event logging, precise timing using clock functionality, and versatile data capture with built-in barcode reading and RFID capabilities, ensuring seamless operations and comprehensive tracking of events.

Achieve smooth Wi-Fi communication, simplified device setup, and operation, while interactive dashboards provide precise insights for enhancing operational efficiency, making the most of your connected experience.

Our system operates independently, ensuring no reliance on external servers for basic data processing, guaranteeing your data's security and availability.

"Splitting tasks" in the context of manufacturing and production lines refers to a strategic approach to manage and execute tasks more efficiently. This technique involves breaking down a larger task into smaller, manageable parts, each with instructions and timelines. The goal is to enhance flexibility, productivity, and adaptability in the manufacturing process. Here's an in-depth understanding of how task splitting benefits this domain.

Manufacturing downtime leads to substantial financial losses, averaging $260,000 per hour, necessitating real-time monitoring and early intervention provided by Iwoscan to prevent costly disruptions.

Frequent machine breakdowns disrupt production, costing up to 3% of annual revenue. Iwoscan's tracking and analysis enable proactive maintenance, reducing the impact of unplanned downtime.

Frequent equipment failures disrupt production schedules. Iwoscan's real-time monitoring and analysis detect issues early, allowing timely maintenance to prevent costly equipment breakdowns and downtime interruptions.

Operator errors reduce production efficiency. Iwoscan's tracking identifies operator-specific issues, enabling targeted training and performance improvements, ultimately minimizing operator-related challenges and production slowdowns.

Manufacturing schedules require precision, and task splitting provides a granular approach to scheduling. Whether a task needs to start, pause, or resume at specific times, this technique allows for accurate scheduling down to smaller increments, such as 15-minute intervals.

The ability to split tasks not only streamlines operations but also contributes to stress reduction. With everything under control and a more adaptable workflow, teams can focus on efficient production without the burden of constant rescheduling and adjustments.

Imagine a reality where efficiency is second nature, productivity soars, and bottlenecks vanish. We're about to unveil solutions that will make your workplace a hub of unparalleled excellence.

Let's make your vision a reality!

Manufacturing defects refer to faults or imperfections in products or components that do not meet specified quality standards. They are a concern because they can lead to reduced product quality, increased production costs, and decreased customer satisfaction.

Iwoscan is a versatile tool designed to monitor various aspects of production processes. It can track and analyse manufacturing defects in real time, providing insights into when and where defects occur. This data helps businesses identify and address the root causes of defects, leading to improved product quality.

Iwoscan can be customised to detect and track defects, including dimensional inaccuracies, material flaws, assembly errors, and more. It can capture defect frequency, location, and severity data, allowing for targeted quality improvements.

Iwoscan helps reduce the need for costly rework, scrap, and warranty claims by promptly identifying and addressing manufacturing defects. This leads to cost savings and increased operational efficiency.

Yes, Iwoscan is designed for seamless integration into various manufacturing setups. It can be adapted to work alongside existing quality control measures and equipment, ensuring minimal disruption to production workflows.

Yes, Iwoscan's flexibility suits businesses of all sizes, from small-scale operations to extensive manufacturing facilities. It can be tailored to meet different organisations' needs and budget constraints.

Iwoscan is user-friendly and comes with comprehensive training and support. While some training may be necessary to maximise its potential, it is designed to be accessible to manufacturing teams with varying levels of technical expertise.

Businesses can expect improved product quality, reduced production costs, enhanced customer satisfaction, and greater operational efficiency. Iwoscan helps companies to achieve a defect-free manufacturing environment.

Yes, Iwoscan can complement existing quality control tools and methodologies. Its data can be integrated into broader quality management systems for a comprehensive defect monitoring and prevention approach.

The timeline for results can vary depending on the specific manufacturing processes and the extent of defects. However, many businesses report noticeable improvements in product quality and defect reduction shortly after implementing Iwoscan.